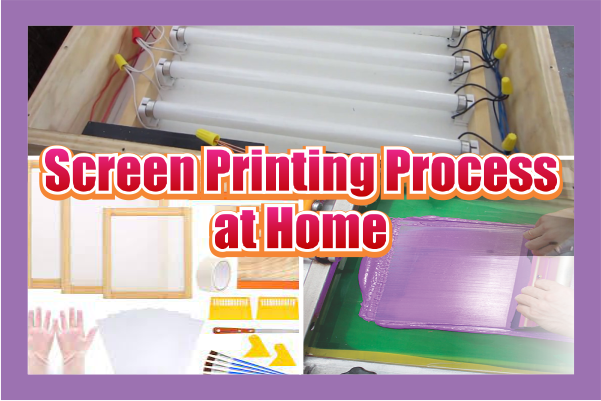

Screen printing process has been an essential part of graphic design and print production for decades. From T-shirts to posters, wedding card, screen printing has been used to create high-quality, visually appealing prints on a wide range of materials. In this blog post, we’ll take you through the screen printing process, explaining each step in detail, from preparation to printing and finishing.

Table of Contents

History of Screen Printing

Screen printing, also known as serigraphy, has its roots dating back to the 18th century in China. However, it wasn’t until the 1960s that screen printing became a popular medium for graphic design and print production. The process was initially used for printing large format posters and has since been adapted for various applications, including T-shirt printing, stickers, and vinyl signage.

The Screen Printing Process

The screen printing process involves several steps:

Step 1: Preparation

Design and Pre-Production:

The first step in the screen printing process is to create a design for the print. This involves creating artwork on a computer using specialized software, such as Adobe Illustrator or Photoshop. The design should be optimized for the intended material and printing method.

Preparing the Screen:

Screens are typically made from a mesh material, such as polyester, nylon, or stainless steel. The mesh is stretched over a frame, allowing ink to pass through the openings, and creating the print.

Coating:

A light-sensitive emulsion is applied to the screen to create a photographic image.

Step 2: Design and Film Production

Creating a Film Positive:

A film positive is created from the design using a film recorder or a photo copier. This produces a negative image of the design.

Exposing the Screen:

The film positive is then used to expose the emulsion on the screen. Light passes through the positive and hardens the emulsion where the design is intended.

Drying and Inspecting:

After exposure, the screen is dried and inspected for any errors or imperfections.

Step 3: Coating and Exposure

Applying the Emulsion:

The light-sensitive emulsion is applied to the screen using a process called “coating.”

Exposing and Drying

The design is then exposed to a light source, and the emulsion is hardened where the design is intended.

Step 4: Drying and Inspection

Drying the Screen:

The screen is dried to ensure the emulsion is hard and ready for printing.

Inspecting the Screen

The screen is then inspected for any errors or imperfections.

Screen Printing Equipment and Supplies

Screen printing equipment and supplies are essential for the process. Some common equipment and supplies include:

Printing Press:

A screen printing press is used to hold the screen in place and apply pressure during printing.

Screens:

Screens are made from a mesh material and are stretched over a frame to create the print.

Emulsion:

Light-sensitive emulsion is applied to the screen to create a photographic image.

Ink:

Ink is used to create the print. There are various types of ink available, including water-based, solvent-based, and UV-curable ink.

Stencils:

Stencils are used to apply a layer of ink to the screen before printing.

Rakes:

Rakes are used to spread the ink across the screen.

Screen Printing Techniques

There are several screen printing techniques used in the industry, including:

Push Printing:

A traditional technique used for printing small to medium-sized prints.

Pull Printing:

A technique used for printing large, high-quality prints.

Hand Printing:

A technique used for creating unique, hand-made prints.

Multi-Color Printing:

A technique used for printing multi-colored prints.

Common Challenges in Screen Printing

Some common challenges in screen printing process include:

Screen Drying:

Inadequate drying of the screen can lead to uneven ink distribution and poor print quality.

Ink Bleeding:

Ink bleeding occurs when the ink spreads beyond the desired area, resulting in an uneven print.

Screen Fading:

Screen fading occurs when the emulsion breaks down over time, requiring the screen to be re-coated and re-exposed.

Conclusion

Screen printing is a versatile and creative process used to produce high-quality prints on a wide range of materials. Understanding the screen printing process, equipment, and techniques can help artists, designers, and print makers to produce stunning prints.